Operational excellence is the holy grail for many organizations wanting to outthink, outpace, and deliver value to customers unlike competitors. Operational excellence is defined as being able to run your organization with minimal variance to established standards for cost and resources while enhancing customer satisfaction – exceeding their expectations. The big secret – we focus on how you can improve your processes using streamlining processes as a methodology to achieve operational excellence. When processes are left with superfluous steps, delays or miscommunications, team productivity declines. Your team is expending energy managing complexity not focused on meaningful work. Streamlining processes eliminates those impediments, providing a straight path to efficiency from beginning to end. This blog post will explore how you can systematically streamline work processes in your organization to reach operational excellence. We will cover definitions, challenges, approaches, resources and how to measure improvements. At the end you will have an approach to enhance your workflows, eliminate waste and build a continuous improvement mind-set.

What Does “Streamlining Processes” Mean?

Streamlining processes means reviewing your current workflows and removing any unnecessary steps, bottlenecks, or redundancies. The goal is to make each step purposeful and efficient, so the overall process flows naturally, saving time, money, and effort.

Imagine a factory conveyor belt where each part moves seamlessly from one station to another without delays or confusion. That’s the essence of streamlining processes—creating smooth, efficient workflows that minimize friction, waste, and errors.

In everyday terms, think about how your favorite app loads instantly without lag or clutter. Behind the scenes, thousands of lines of code and multiple systems work together in a streamlined way to deliver a smooth user experience.

What is Operational Excellence in Modern Business?

Operational excellence is not only about lowering costs or running faster, but it is the all-around approach of being able to provide products and services consistently at the highest quality level, while also being flexible and sustainable. Within a company that reaches operational excellence, there are three areas affected in a positive way: efficiency, adaptability to market needs, and use of resources that minimize waste and maximize value while facilitating an operational culture and model of sustained continuous improvement. Operational excellence is the even distribution of people, processes, and technology that work cohesively to “get it right every time,” according to experts.

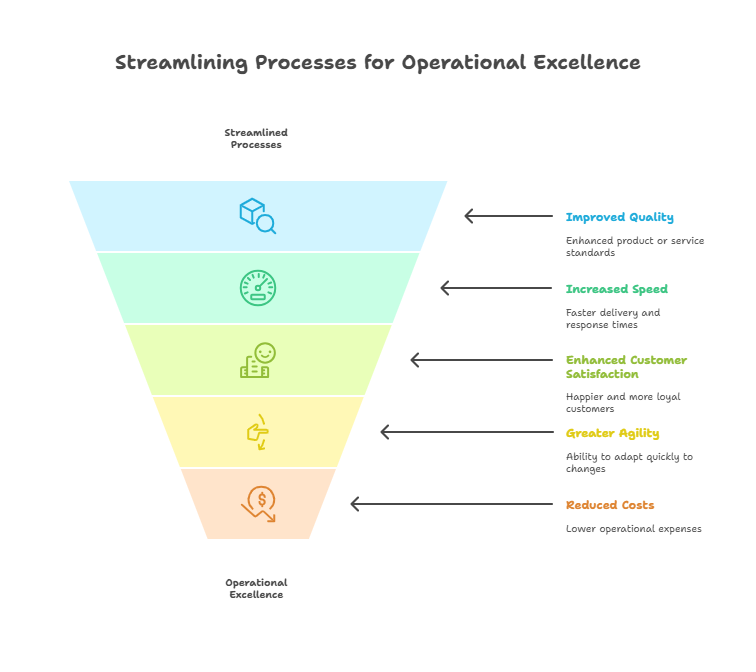

Why Streamlining Processes is Important for Operational Excellence

Streamlining is the basis for operational excellence. Once you achieve lean, efficient processes, you’re improving quality, speed, customer satisfaction and agility while reducing costs. A good example is a streamlining order fulfillment process. A streamlined process can not only speed up deliveries but also improves accuracy and reduces customer complaints providing a strong brand reputation and higher profits.

The Hidden Cost of Inefficiency

While most companies view lost time or money as a cost of inefficiency, the repercussions of inefficiency don’t just stop there. Inefficiencies develop fatigue in your employees due to battle fatigue and the overall frustration of repeating poor processes. According the the American Institute of Stress, over 80% of workers are under stress related to their jobs and companies using inefficient processes whether due to fatigue or simply missed opportunities from customers and prospective customers, as well as increased friction inside teams. According to industry research, companies could be losing up to 30% of their revenue as a result of inefficient operations, and many companies don’t even realize how much they lose until they focus on improving their processes.

Principles of Streamlining Processes for Operational Excellence

Before diving into specific strategies, it’s important to understand the foundational principles that guide process streamlining:

- Customer-Centricity: Every process should ultimately serve the customer’s needs. Remove steps that don’t add value from their perspective.

- End-to-End Process View: Look beyond departmental silos. Optimize the entire value chain rather than isolated tasks.

- Standardization: Create consistent workflows to minimize variability and errors.

- Continuous Improvement: Adopt a mindset of ongoing refinement using feedback and data.

- Automation: Use technology to handle repetitive tasks, freeing up human resources for higher-value work.

- Employee Empowerment: Involve frontline employees in identifying bottlenecks and testing improvements.

These principles ensure that streamlining efforts align with your larger business goals and foster a culture of operational excellence.

Common Challenges Businesses Face in Process Streamlining

Even with the best intentions, many organizations stumble when trying to streamline. Understanding common pitfalls can help you avoid them:

- Lack of Clear Objectives: Without defined goals, efforts become scattered and ineffective.

- Resistance to Change: Employees may fear losing control or jobs, slowing adoption.

- Siloed Thinking: Departments optimize locally but ignore impacts on overall flow.

- Insufficient Data: Decisions without accurate process data are guesswork.

- Over-automation: Automating flawed processes magnifies problems instead of fixing them.

- Ignoring Culture: Process improvements fail without buy-in and engagement.

Recognizing these challenges upfront allows for better planning and management of your streamlining initiatives.

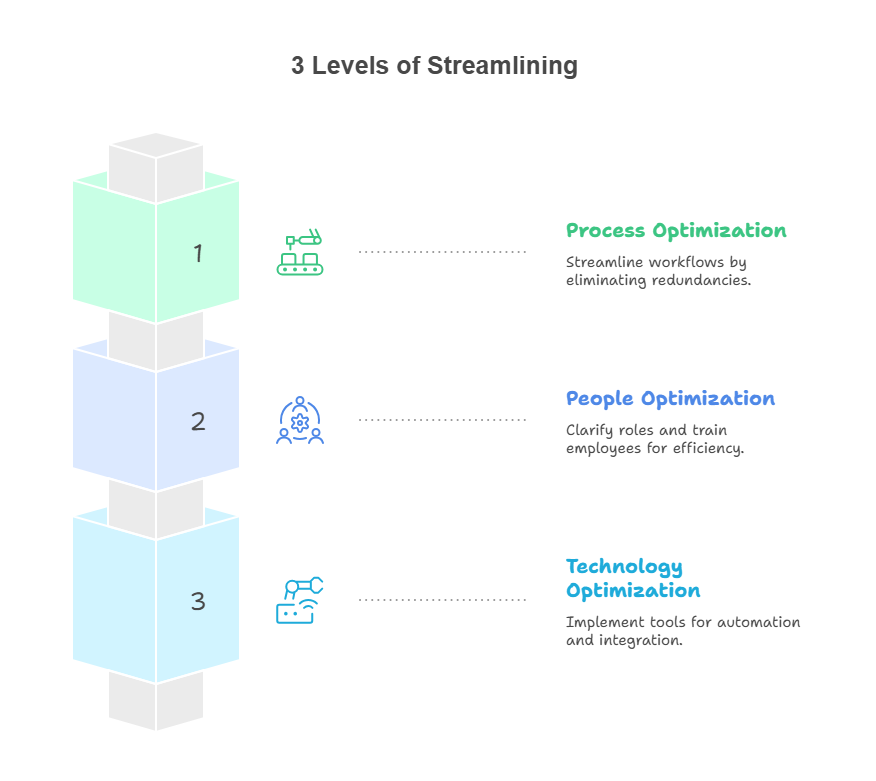

3 Levels of Streamlining: Process, People, and Technology

Many organizations focus solely on process redesign when streamlining, but that’s just one piece of the puzzle. To truly excel, you need to optimize three interconnected layers.

First, process optimization means mapping your workflows and redesigning steps to eliminate redundancies or delays. For example, simplifying a delivery process by cutting unnecessary approvals.

Second, people optimization involves clarifying roles, breaking down silos, and training employees so they can perform their tasks efficiently and adapt to new workflows. Engaged and informed teams are critical for success.

Third, technology optimization involves implementing the right tools to automate repetitive work, integrate systems, and provide real-time visibility. Using automation to handle routine invoicing or customer notifications can free your team for higher-impact work. By balancing process, people, and technology improvements, your business becomes agile, efficient, and resilient.

By deliberately balancing process, people, and technology improvements, your business will be agile, efficient, and resilient.

Benefits of Streamlining Processes

When you streamline processes, the benefits extend far beyond immediate efficiency gains. Here’s a deeper look at what you gain:

- Accelerated Cycle Times: Lean workflows reduce delays, speeding up delivery or service.

- Improved Quality and Consistency: Standardization and automation cut down errors.

- Cost Savings: Less rework and wasted effort mean lower operational expenses.

- Enhanced Customer Experience: Faster, error-free services boost satisfaction and loyalty.

- Employee Engagement: Clear processes reduce frustration and free employees for creative work.

- Better Compliance and Risk Management: Documented workflows ensure adherence to standards and reduce errors.

| Benefit | Impact Example |

|---|---|

| Faster cycle times | 30% faster product launch |

| Higher quality | 50% fewer customer complaints |

| Cost reduction | 20% savings in operational expenses |

| Customer satisfaction | 15% increase in Net Promoter Score (NPS) |

| Employee engagement | Reduced turnover by 10% |

| Compliance adherence | 100% audit success rate |

Start your journey by identifying and mapping current workflows. Use flowcharts or value stream mapping to visualize every step and handoff, exposing inefficiencies you might not see day-to-day. Next, find bottlenecks and redundancies by analyzing data and gathering frontline employee insights.

Involve your team early in the process to get their feedback and build buy-in. Standardize where possible through clear SOPs and checklists. Challenge old habits and remove or combine steps that don’t add value.

Automate repetitive tasks using technology platforms to free human time. Monitor progress continuously with KPIs and Objectives and Key Results (OKRs). Finally, embrace continuous improvement by regularly revisiting processes and iterating based on new data and feedback.

Streamline Process Flow

A clear example of streamlined workflow is a customer support process:

- A customer inquiry is automatically logged in the system.

- AI categorizes and prioritizes tickets.

- Tickets are assigned to agents based on expertise.

- Agents use standardized templates to speed response.

- Automated reminders ensure timely resolution.

- Feedback surveys are sent post-resolution.

- Managers track metrics in dashboards to improve further.

This flow cuts down manual steps and delays, improving resolution times and satisfaction.

Streamline Process Examples

Different industries streamline their workflows based on unique needs. Implementing systems like task tracking and time management can improve operational efficiency and speed up project delivery by up to 25%. Small businesses use integrated resource management to reduce administrative tasks and shorten billing cycles by 30%. Startups leverage AI-powered collaboration and workflow automation to accelerate product launches and minimize errors. Service teams centralize ticket management and standardize communication to resolve client issues faster and boost customer satisfaction.

To maximize impact, businesses must tailor process improvements and adopt the right tools that fit their specific context.

Streamline Process Improvement

Streamlining is a continuous journey. Audits provide a check on adherence to processes and allow for identifying new bottlenecks. Use the ‘5 Whys’ for root cause analysis into the details of issues. Use employee feedback to gain valuable insights from the frontline. Lean and Six Sigma methods can provide structured frameworks to carry out improvements, typically with DMAIC cycles. Key Performance Indicators (KPIs) and dashboards allow for measurable and focused data driven decisions for process improvement. Trial pilot changes prior to rollout to scale them. Continuously train your teams and provide them awareness to maintain sustained growth. Continuous improvement allows you to make your operations resilient and convertible.

Conclusion

While looking for operational excellence through process improvement seems impossible, each journey begins with a step in the right direction. Start by mapping a small, important workflow while working with the whole team to find improvements.Always remember the rewards are far-reaching, from faster delivery, improved quality, satisfied customers, and an engaged workforce. Maintain the momentum by committing to continuous improvement and leverage smart technology that reduces friction across teams like Whitepanther.

Do something today, identify one process that is a pain point for your team or slows you down. Pencil map it out, ask for feedback, and implement one meaningful change.

Try Whitepanther to Streamline Your Workflows

Whitepanther is designed to combine project management, communication, collaboration, and AI into a single platform. It aims to reduce app switching, accelerate output, and bring clarity to cross-functional tasks. Built to transform business workflows. Join the Whitepanther waitlist today and transform your business workflows.

FAQ‘s

How long before I see results?

Most companies notice improvements within 3 to 6 months.

Can small businesses benefit?

Yes, startups and SMEs gain a lot from early process optimization.

Is automation required?

Not always. Simplify and optimize processes and people first, then automate.

How to handle resistance?

Communicate openly, involve teams, celebrate wins, and appoint champions.